MsRWA Apprenticeship Program

Click the button bellow to sign up and employee for the MsRWA Apprenticeship Program.

Deadline for next class is TBA soon!

Sign up for Apprenticeship ProgramLIHWAP

Watch the recorded Webinar we hosted to help understand the LIHWAP. Click the button below.

Watch the Informative Video RegardingThe Voice for Rural Water

Previous slide

Next slide

The mission of MsRWA is to provide leadership, training programs, technical assistance and services to meet the needs of all our state’s utility members.

The Voice for Rural Water

Watch the video to learn about the history of water service in rural Mississippi, and see some of the ways MsRWA helps its membership to provide clean, safe water to rural residents today.

2024 Tishomingo County Job Fair – MDES

January 18, 2024

MDES JOB FAIR January 25, 2024 9:00 AM – 1:00 PM Iuka Fairgrounds Building 108 County Road 187 Iuka, MS TO PROMOTE THE HIRING OF

MsRWA Job Opening – Apprentice Program Manager

August 22, 2023

Job Announcement Date: August 17, 2023 Job Announcement Closure Date: August 25, 2023 (with reservation to close prior to without further notice) Position Title: Apprentice

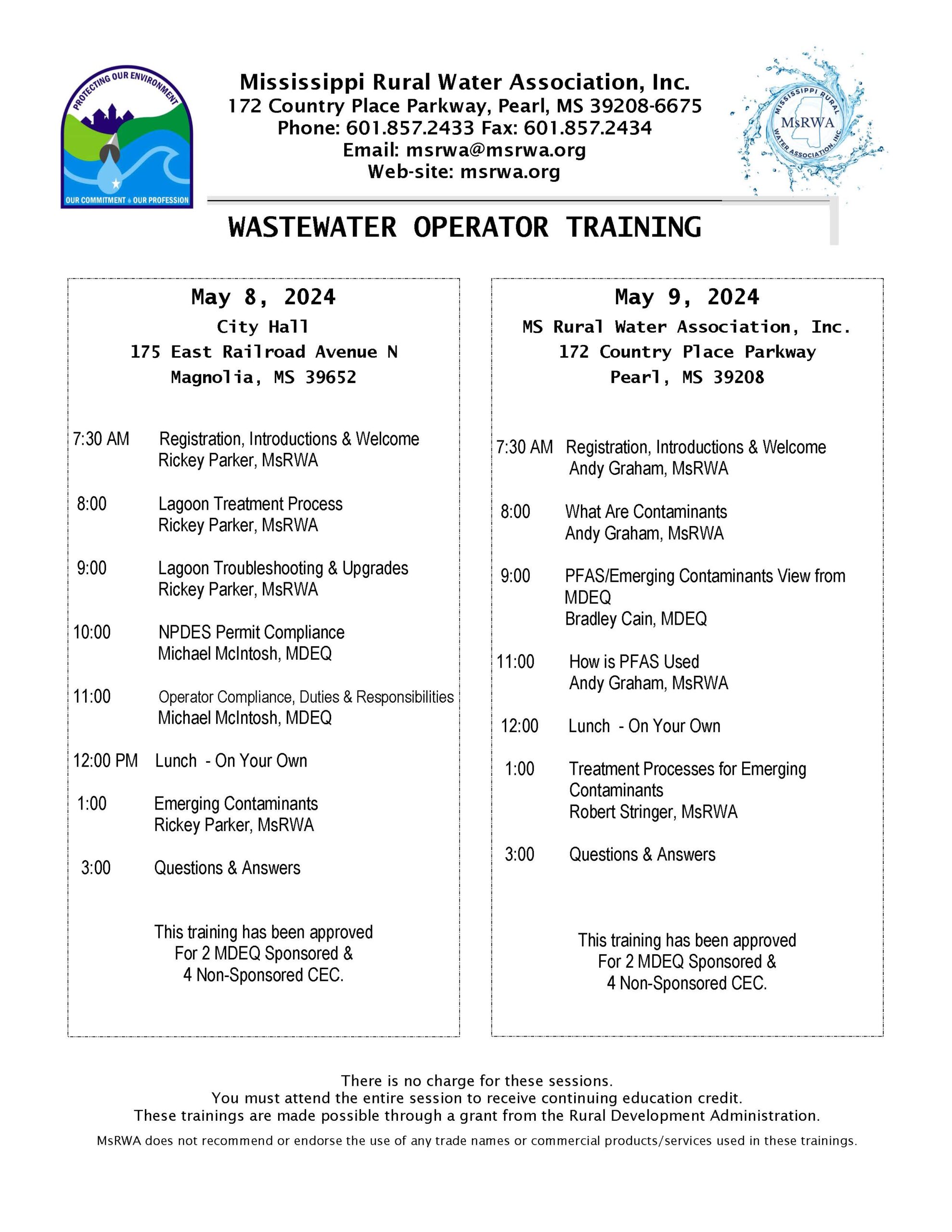

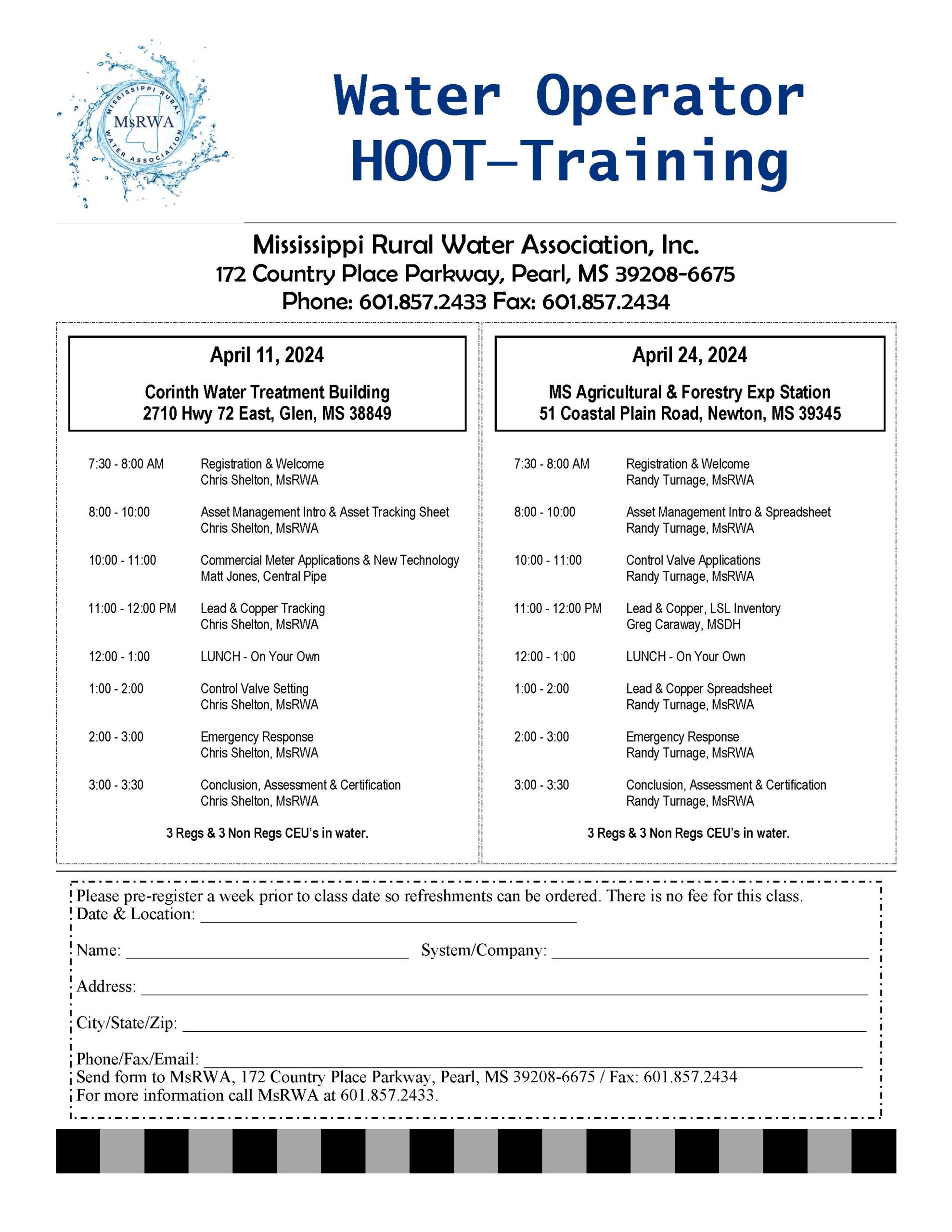

Apr

24

Wed

2024

7:30 am

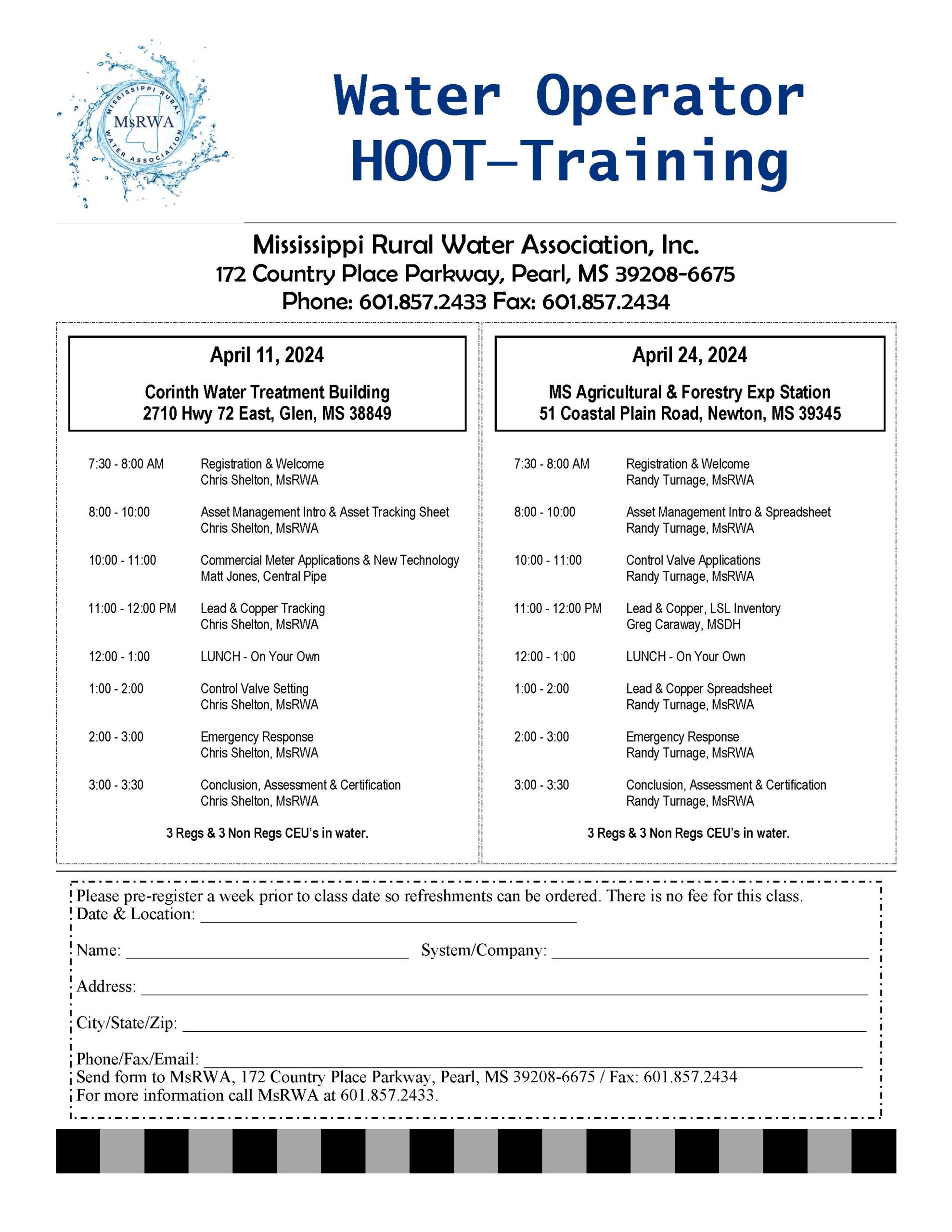

HOOT Training – 3R/3NR – Newton

@ MS Agricultural & Forestry Exp Station

HOOT Training – 3R/3NR – Newton

@ MS Agricultural & Forestry Exp Station

Apr 24 @ 7:30 am – 3:30 pm

Please submit a separate form for each attendee.

Apr

29

Mon

2024

7:30 am

Backflow Certification Training

@ MsRWA Office

Backflow Certification Training

@ MsRWA Office

Apr 29 @ 7:30 am – May 2 @ 4:00 pm

Registration Fee: $450 Download the PDF Registration Form Or submit the form below:

May

2

Thu

2024

7:30 am

Backflow Recertification Training

@ MsRWA Office

Backflow Recertification Training

@ MsRWA Office

May 2 @ 7:30 am – 4:00 pm

Registration Fee: $225 Download the PDF Registration Form Or submit the form below: